| Qantel Product Resources |

|

Print Labels from PowerShift

Randy Eding CPIM CIRM CSCP, PowerShift Product Manager, Qantel

Technologies Inc.

Tags and labels identify items; the essential difference is that labels

are printed on stock with an adhesive backing so they can easily be

affixed to products.

PowerShift’s Document Management System provides the ability to print

custom tags and labels as part of the process of generating standard

documents such as purchase orders and receivers.

Two examples include generating labels at time of stock receipt

(purchased or manufactured items) and creating labels with

product/content information to support shipping to customers.

Labels and tags use data from PowerShift and can be created with

Report Generator, QICLOOK, QICBASIC programs, or external label

applications.

Some PowerShift users private label goods for a variety of customers

with each customer having a unique product label format requirement.

When you look at the labels you quickly see that much of the

information is the same and only the label format changes from one

customer to another. A

third-party label application can make quick work creating such

customer-specific labels.

First, you determine which variable data elements are required to

produce any of the labels and provide this information to the label

interface. Feed the label

application as many variables as you want; only those needed for the

printing of each unique label are utilized.

Use the label software to design how the label will look.

By setting up a user field to identify the label design for each

customer, the label application can be fed the variable data elements as

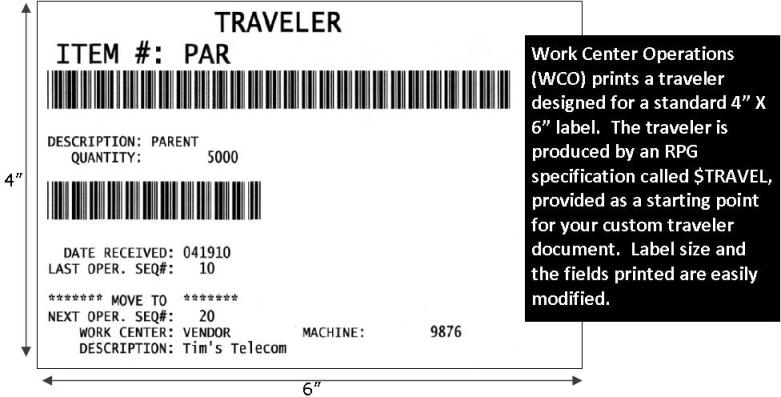

well as the design to use. When you reject an item you can print an MRB tag that includes all of the pertinent data to fulfill the ISO documentation requirement to identify parts on the production floor. The Work Center Operations (WCO) inquiry includes an option to print a traveler that can accompany the product to the next operation or to the stock room. The identification tag can include any data that is pertinent to your operation; data such as the item number and quantity being moved can be bar coded for use at subsequent steps. Based on the product’s routing, you can list the work center that the material is to be moved to for the next manufacturing operation – or if you have completed the last operation you can indicate that the items be moved to the stockroom. You can also include the primary warehouse and bin location for stocking the item. Once set up in WCO, the operator simply selects an operation and presses the Traveler button. The operator is prompted to enter the quantity being moved and the document is immediately printed. Voila! No more illegible handwritten documents to try and decipher.

Label/tag printers come in a variety of styles and can conveniently be

located anywhere via wireless

connections.

|

|

|

|